Machine Optimization & Data Collection

Automation Process Tuning and Adjustment

Machine-centric Optimization and Data Collection Platform

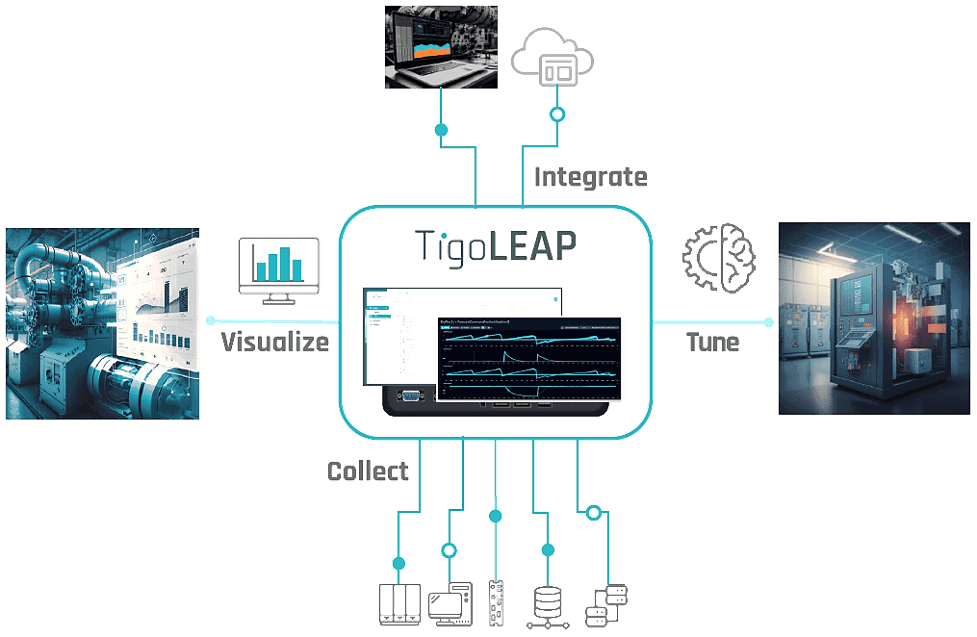

TigoLeap is a software platform for industrial high-speed and synchronous collection and analysis of multi-source OT data. It revolutionizes the methodology of developing machines by providing the tools to visualize, store and share automation and testing related data.

Focusing on performance improvement and machine optimization, it enables collection of all data types from the machine, root-cause analysis, machine tuning, adjustment of models/processes, and remote access. It is a machine-centric platform with a range of tools and services to enable ongoing optimization of OEE, ramp-up time reduction and optimization, insight generation, and enhanced remote support capabilities.

TigoLeap Benefits

Efficient process tuning, collaboration, enhanced access

Data Accessibility

Time to Market

Process Tuning

Team Collaboration

Remote Support

Multiple Interfaces

Machine Optimization Platform Use Case

Adaptive Process Tuning

A packaging machinery builder of adaptive machines that can adjust for a variety of package types has encountered issues with adjusting the grip force to the changing package types. Such mis- adjustments result in occasional mishandling of materials (either dropping or over-picking) which translate into machine downtime and manual intervention that affects the overall OEE of the production line.

Supporting each machine by an on-premise expert to resolve this issue and adjusting the machine is inefficient and does not enable finding a solution in a timely manner. Through data collection, analysis and machine learning algorithms, an adaptive parameter model could be found that brought the efficiency up.

A packaging machinery builder of adaptive machines that can adjust for a variety of package types has encountered issues with adjusting the grip force to the changing package types. Such mis- adjustments result in occasional mishandling of materials (either dropping or over-picking) which translate into machine downtime and manual intervention that affects the overall OEE of the production line.

Supporting each machine by an on-premise expert to resolve this issue and adjusting the machine is inefficient and does not enable finding a solution in a timely manner. Through data collection, analysis and machine learning algorithms, an adaptive parameter model could be found that brought the efficiency up.

"The adaptive process tuning system measures the process on the spot. The algorithm optimizes the settings of the machine - the machine is learning itself without the intervention of operators in order to run its own optimized settings. Having the wireless communication there helps a lot, it was not possible in the past due to blind spots - that's resolved today thanks to IO-Link Wireless. "

Manu Peelman

Principal Technical Program Manager

How Does it Work

Observe, Analyze, Adapt

Data Collection – An edge data collection device that enables short-term data capturing for high-speed analysis, agnostic real-time data capturing of large amounts of data, reading/writing parameters from/to the PLC with a high-resolution, and buffering of data that needs to be sent to the cloud. The module includes advanced device management tools to manage and connect multiple data sources and define logical data flow.

Adaptive Process Tuning – A unique process optimization tool for continuous output evaluation and machine parameter adaptation. It employs artificial intelligence and machine learning algorithms for ongoing machine optimization. The tool enables learning and understanding which parameters have impact on the result of the machine’s process/operation and automatically or semi-automatically tuning it.

Enhanced Remote Service & Support – Remote access tools for system configuration management, troubleshooting, real-time secure data collection and analysis. Remote access of multiple machines deployed at multiple sites also enables comparing machine performance levels and benchmarking.

CoreTigo’s Machine Performance Optimization Platform is designed to be user friendly and cost-effective to fit both existing and new machines. The platform ensures OT level reliability and security, offers both cloud and on-premise connectivity and allows for efficient remote expert support. The solution collects, stores and processes the collected data, along with device management functionality, AI/ML tools, and remote support/access.

Data Collection – An edge data collection device that enables short-term data capturing for high-speed analysis, agnostic real-time data capturing of large amounts of data, reading/writing parameters from/to the PLC with a high-resolution, and buffering of data that needs to be sent to the cloud. The module includes advanced device management tools to manage and connect multiple data sources and define logical data flow.

Adaptive Process Tuning – A unique process optimization tool for continuous output evaluation and machine parameter adaptation. It employs artificial intelligence and machine learning algorithms for ongoing machine optimization. The tool enables learning and understanding which parameters have impact on the result of the machine’s process/operation and automatically or semi-automatically tuning it.

Enhanced Remote Service & Support – Remote access tools for system configuration management, troubleshooting, real-time secure data collection and analysis. Remote access of multiple machines deployed at multiple sites also enables comparing machine performance levels and benchmarking.

CoreTigo’s Machine Performance Optimization Platform is designed to be user friendly and cost-effective to fit both existing and new machines. The platform ensures OT level reliability and security, offers both cloud and on-premise connectivity and allows for efficient remote expert support. The solution collects, stores and processes the collected data, along with device management functionality, AI/ML tools, and remote support/access.